Getting the groceries you ordered!

Client: Kroger Customers

Role: Senior Product Designer and Inventory Expert

Worked with designers in customer experience to discover, define, develop & deliver the experience.

Cross department collaboration between customer experience and supply chain. Collaborated with multiple product managers, product designers, engineers, program managers, stakeholders and design research

Background

Customer experience and supply chain worked together to provide a better inventory experience.

This started with a week long focused workshop to understand our respective product spaces and continued with several discovery sessions, research, testing, iterations and weekly touch point meetings.

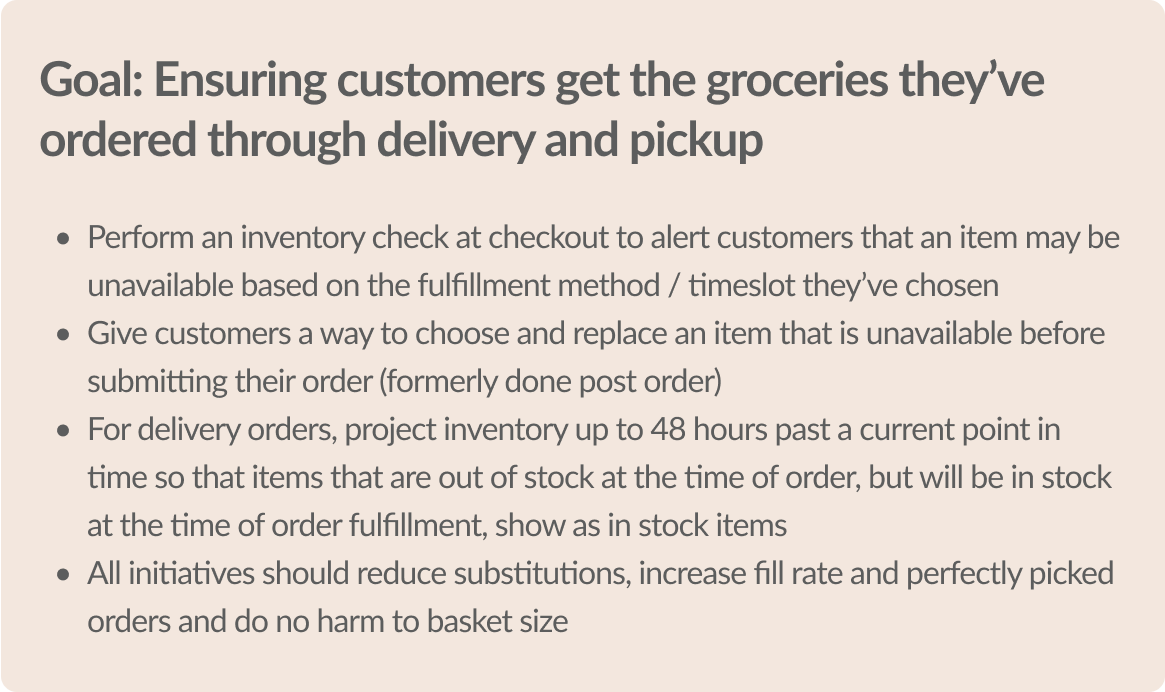

This project took over a year to complete and involved many product teams, stakeholders and leadership buy-in to carry-out the combined 3 initiatives:

Inventory check at checkout

Item replacement

Projected inventory

Challenges and Risks

There was a concern that business (increased fill rate) was driving the teams to build something that wouldn’t add value to the customer. In fact, there were concerns that adding an inventory check at checkout would cause additional fallout later in the shopping experience causing frustration.

Additionally, there were questions on whether giving a customer an option to replace an item that was unavailable would cause the customer to abandon their cart because of the additional effort to replace an unavailable item.

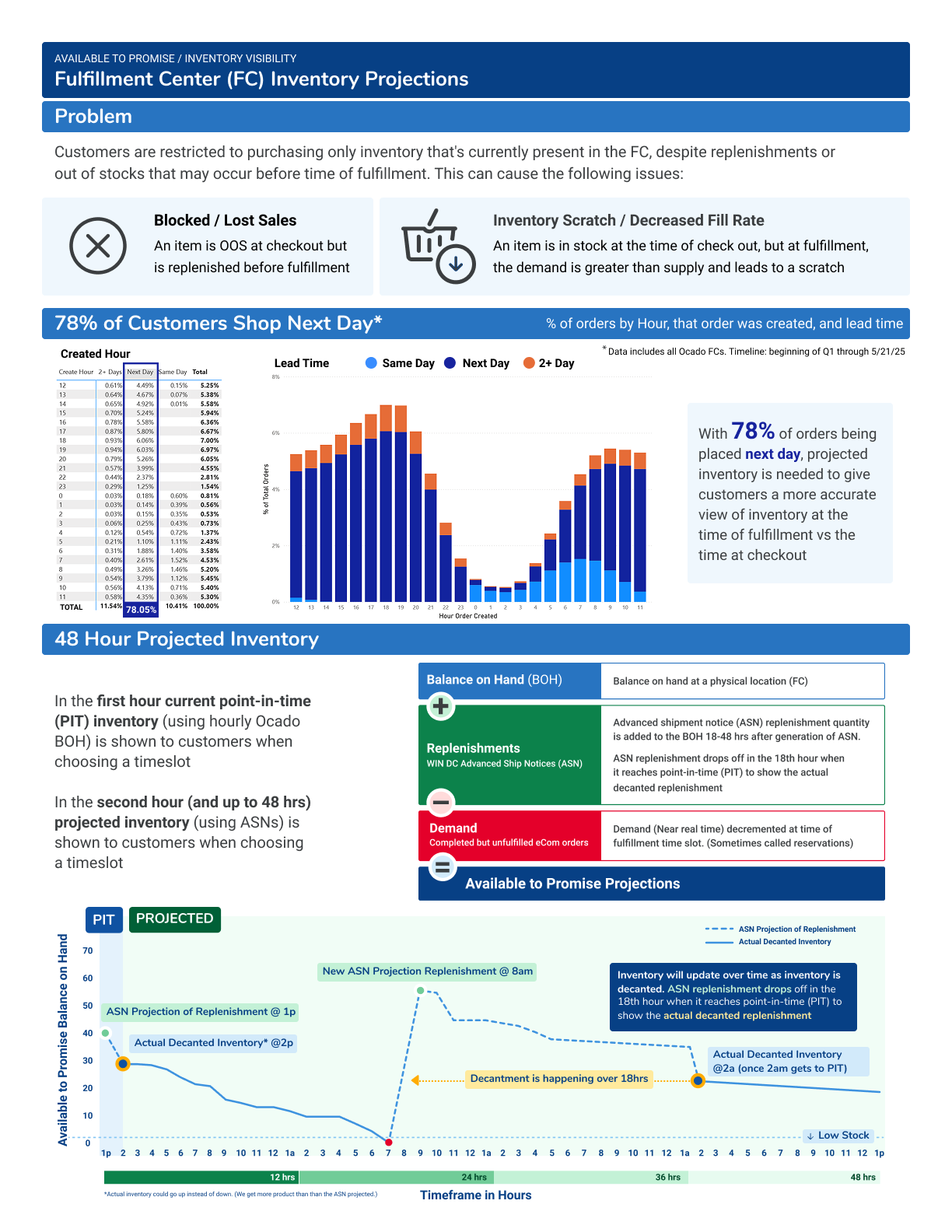

With projected inventory, there was always a concern of accuracy. Blocking sales because the projection is inaccurate.

Workshop 1 Goals

Focus on instilling trust in, and accuracy of Kroger inventory so that customers have confidence they will receive the items they ordered

Share service blueprints and goals of each area

Identify pain points and opportunities

Brainstorm ideas and experiments

Inventory service blueprint with pain points from both customers and the business side. Created and presented by me.

Everyone’s early ideas written down on stickies

Break out groups: Group 1 brainstorm ideas

Notifications of back in stock during & after shopping journey

Break out groups: Group 2 brainstorm ideas

Multiple ideas / paths

Break out groups: Group 3 brainstorm ideas

No dead ends - multi fulfillment methods

Opportunity tree (Theresa Torres) showing our expected outcome of transparency, opportunities and possible solutions

List of experiments and studies needed to test possible solutions

We mapped the experiments we wanted to perform based on the impact and difficulty to determine priorities

Final list of experiments

Point in time (POT) inventory check at checkout.

Review of metrics to see how much fallout would occur by doing an inventory check at checkout. (Led by product management)

Allow customers to choose a backup / replacement item. (Led by product design, design research, and product management)

Inventory research for current and future state

Two rounds of usability testing

A/B testing for item replacement experience

Available to Promise (projected inventory) at checkout. (Led by design research and product design)

Interviews with customers to understand their needs around inventory

Concept testing of projected inventory mockups to get customers’ feedback

Workshop 2 Goals- Item Replacement Focus

Goal: How might we eliminate dead-ends in checkout & ensure that the experience is easy to use?

Design methods and Luma exercises to define the item replacement experience: (Workshop led by me)

Reviewed metrics for substitutions and back up items, time customers spent shopping and various inventory numbers

Competitive analysis (3 shown here). Rose , bud, thorn analysis

Pulled secondary and past primary research

Created storyboards

Rough & Ready Prototyping

Voting

Competitive analysis and rose, bud and thorn exercise

Amazon competitive analysis

Walmart competitive analysis: Most informative

Target competitive analysis

Secondary research: past research and Baynard research

Word cloud of previous research: Customer’s biggest challenges

Previous customer research that talks about wanting to pick their own item for substitution

Research from Baymard Institute related to inventory

Storyboards to help the team get into the mindset of the customer and understand the context surrounding the experience

Wireframes to conceptualize the experience and voting to determine the direction we should take for mockups and testing

By the end of workshop 2, we had a general experience direction to test with customers:

We knew that we wanted to notify customers that there was an unavailable item and for them to replace the item from the scheduler page

However, we needed to test a few options, based on the above wireframes, using higher fidelity Kroger stylized mockups

Workshop 3 Goals: Map our assumptions

Along with testing our wireframes, we wanted to test our assumptions that were both customer facing and internal feasibility questions.

(Helped lead workshop)

We wrote down assumptions that we had about the initiative, identified the riskiest assumptions, categorized them and discussed how we could test them

We categorized our assumptions by desirability, feasibility, viability, ethical and usability

This helped us build a list of questions and test scenarios with our usability tests.

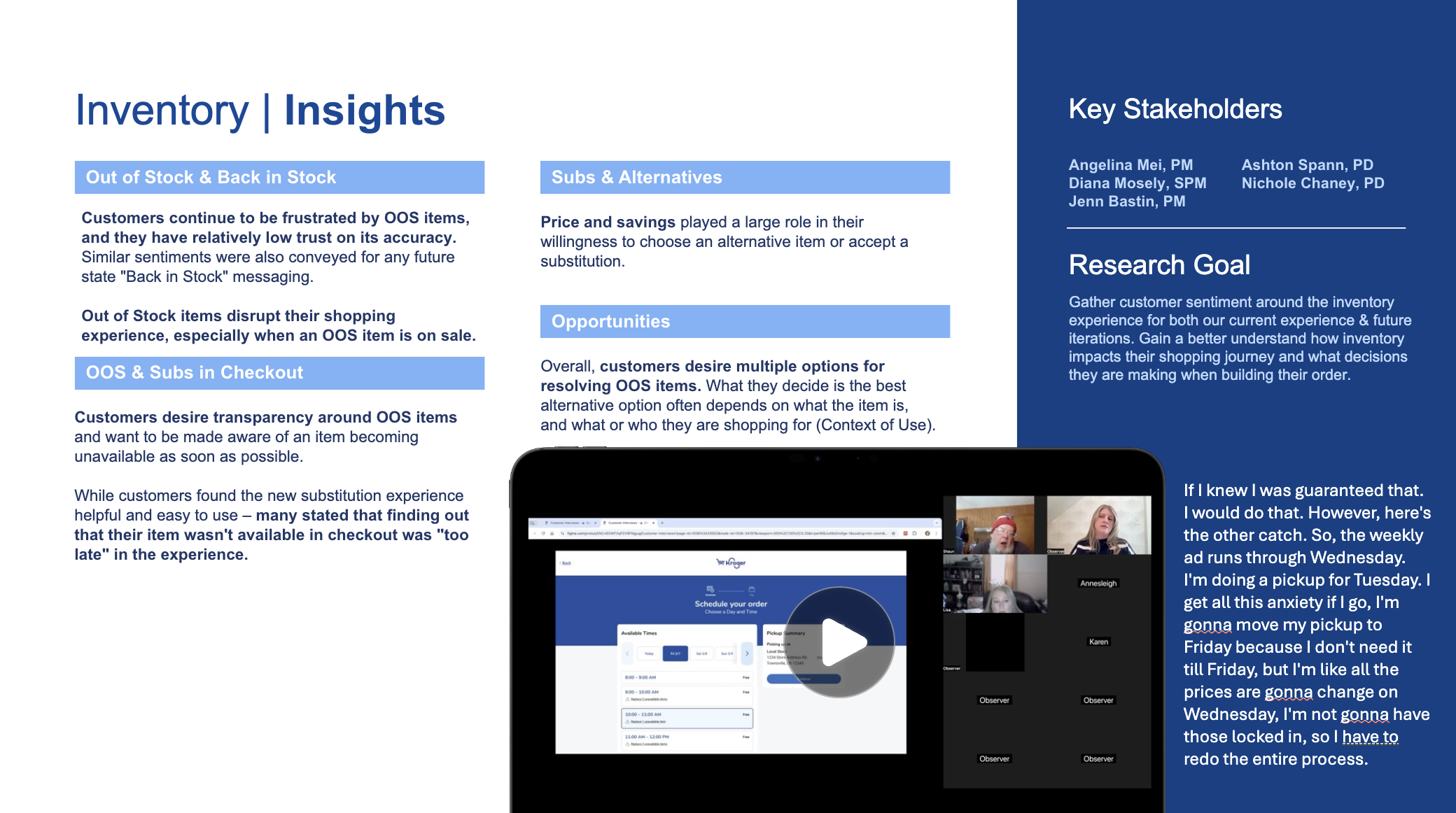

Research: General Inventory and Projected Inventory Research

Goal: Gather customer sentiment around the inventory experience for both our current experience and future iterations. Gain a better understanding of how inventory impacts the customer’s shopping journey and what decisions they are making as they are building their order.

Moderated virtual interview sessions and concept testing with 5 customers.

(Partnered with design research and CX product designers to write questions and conduct interviews. Interviewed participants and presented findings.)

Asked inventory questions to understand customer needs and preferences for out of stock items

Item replacement desirability study and experience feedback

Projected inventory desirability study and experience feedback

Affinity mapping of interview data

Projected inventory experience test

The interview started with asking the customer to think about an item they really like or buy often.

The screen below is showing the product card results from a search and the gray box represents the item that they like or need. We didn’t use a specific item because everyone has different needs / likes and the item that we chose, may not be important to them. We needed to create a sense of urgency for this item and find out what customers would do if they saw the ‘Back in Stock March 8th’ message. Would they pause their order and come back when the item is back in stock? Would they pick it up at their local store etc?

Initial findings, insights and HMW questions

*Sorry, video does not play here due to confidentiality

Research Conclusions

Currently checkout is the place where most customers chooses a fulfillment method (pickup, Kroger delivery, Instacart delivery) and a timeslot; so in the current experience it is not possible to show customers out of stocks sooner. However, we are continuing to iterate to try and get customers to choose the fulfillment and time earlier in the shopping journey.

According to the test, projections should not be used on the product cards because customers do not trust the message of when it will be back in stock.

It was decided that it was best to have projected inventory in the background for Kroger delivery orders. An item would show as in stock if an item was currently out of stock, but was being replenished at the time of fulfillment. Vice versa for orders that were in stock at the time of ordering but would be out of stock, due to demand, at the time of fulfillment.

Designing / Testing the Item Replacement Experience

The item replacement experience was built using:

The Kroger Design System Library

Layout templates from scheduler, product cards, and ‘choose a backup’ in cart

New portions of the experience included being able to view ‘unavailable items’ in scheduler, the replacement flow and the entrance / exits into the experience.

(Collaborated with CX designer to build the new experience. Led the usability testing.)

Usability Testing

Top items to test:

Entry / Exit into experience

Does this benefit the customer?

Customer sentiment

Ease of replacing items

(Engagement /How often would it be used? Later in A/ B testing)

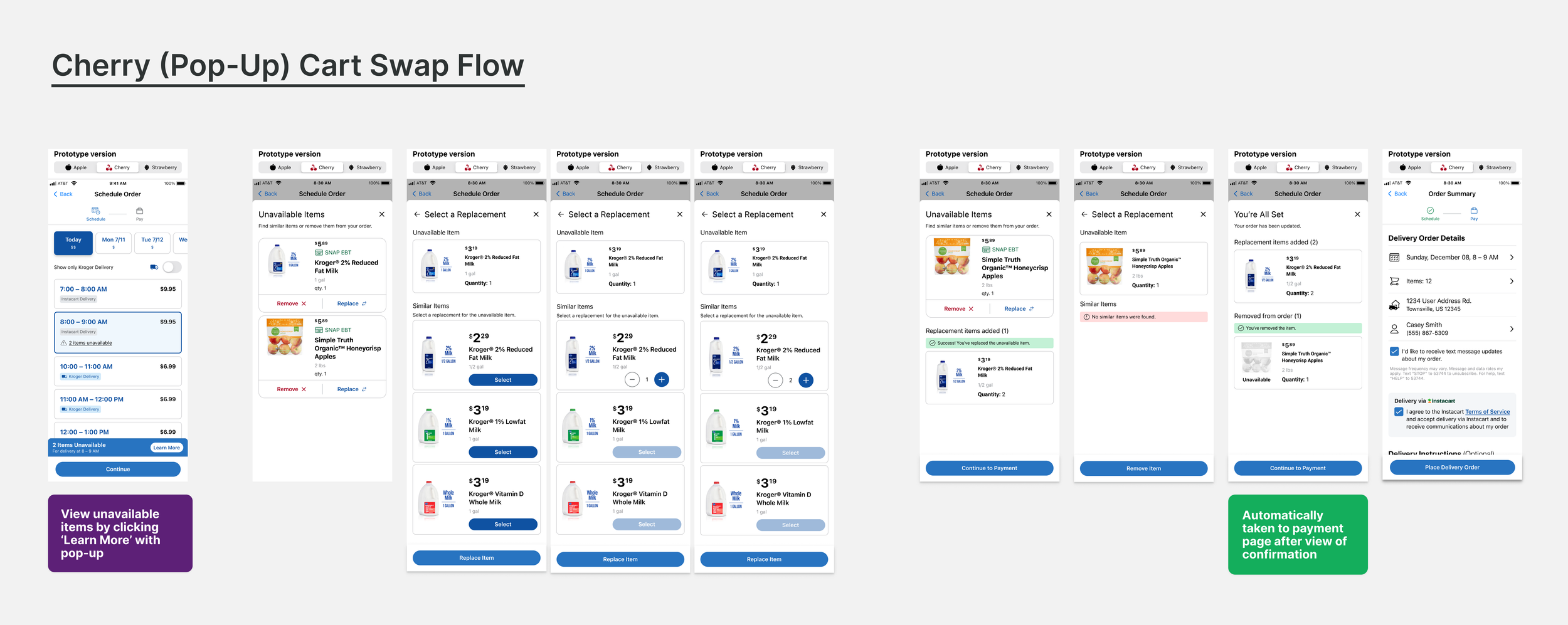

Unmoderated testing of 3 prototypes using Userzoom

Screening for customers who do the majority of the shopping and are Kroger customers

Two tests

1st test- 10 Kroger customers

2nd test- 4 Kroger customers

Usability Test Results from the 2nd Test

Top Findings

1st test: We were on the right path of replacing / removing items, but specific tasks needed to be simplified

Customers were confused with replacing a quantity of 1- 1% gallon milk with a quantity of 2- 1% 1/2 gallon milk. Therefore, in the 2nd test, we had customers. replace a 1 gallon 1% Kroger branded milk with a different brand of 1% gallon milk

There were some technical glitches with the pop-up drawer. We fixed the issue to make the transition seamless.

2nd Test: Participant Success! It's easy to replace / remove items

Customers liked the pop-up drawer the best (cherry); however, it was decided to go forward with the ‘Unavailable Items link’ for MVP because it was straight-forward technically

Customers did find value in replacing an unavailable item!

Item Replacement Experience Iterations

Iterations & minor revisions were completed to ensure a seamless and consistent experience across the shopping journey

Desk checks were conducted with other designers and engineers to ensure a consistent experience

Added the date / time within the item replacement experience to remind the customer of the day / timeslot that was chosen

Copy update for when there is not a similar item:

From: ‘There was a problem retrieving similar items. Please try again.’

To: ‘No similar items were found. Please try a different time to check items' availability.”

Removed ‘black & white’ stylized images when product was unavailable and needed to be replaced

‘qty’ to Quantity

Line was extended across product card

Snap EBT was added to all product cards

Accessibility check and guidance for developers with accessibility tagging

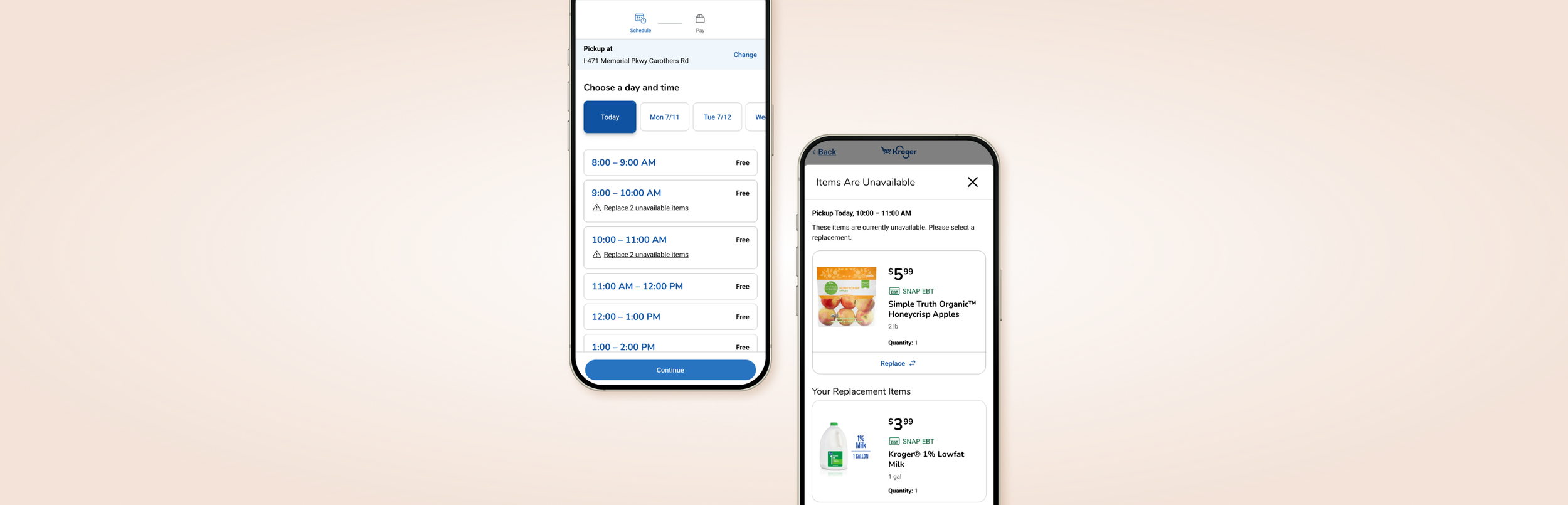

Final item replacement experience. (Happy path for iOS / desktop).

iOS Happy Path

Desktop Happy Path

Conclusion

There was some risk involved with this project because the ideal situation is to never have unavailable items and to keep checkout as simple as possible. Our team will continuously improve the experience and increase availability of all products. Meanwhile, item replacement is a way for customers to get out of a dead end and get an item that is needed.

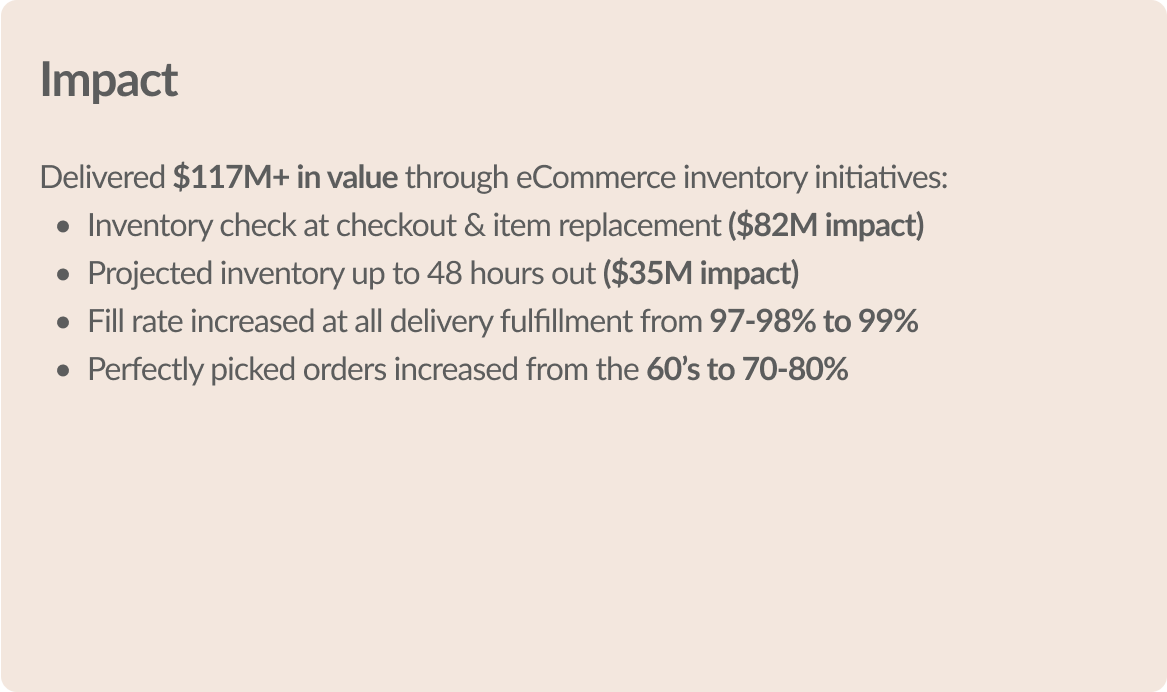

All 3 of these initiatives were rolled out individually after separate A/B testings showed the following:

30% overall engagement rate

Pickup

+9.4% lift in cart adds and +8.7% lift in orders placed within the new experience - both reaching statistical significance

Delivery

Order revenue: Around a +25% lift

Orders and cart adds originating directly from the fallout recovery experience increased by +4% and +1%, respectively

Delivery Customer UserTesting Survey: “I can get all items in my order” ranked highest consistently from Q2 2022 through Q2 2025